Arrow provides various offerings to accommodate for your business operations, the types of vehicles you work with, and the nature of the goods being loaded or unloaded.

Dock levellers provide smooth and safe loading and unloading for your warehouse or industrial facility and is a crucial component of a loading bay system that facilitates the safe and efficient movement of goods between a loading dock and a vehicle.

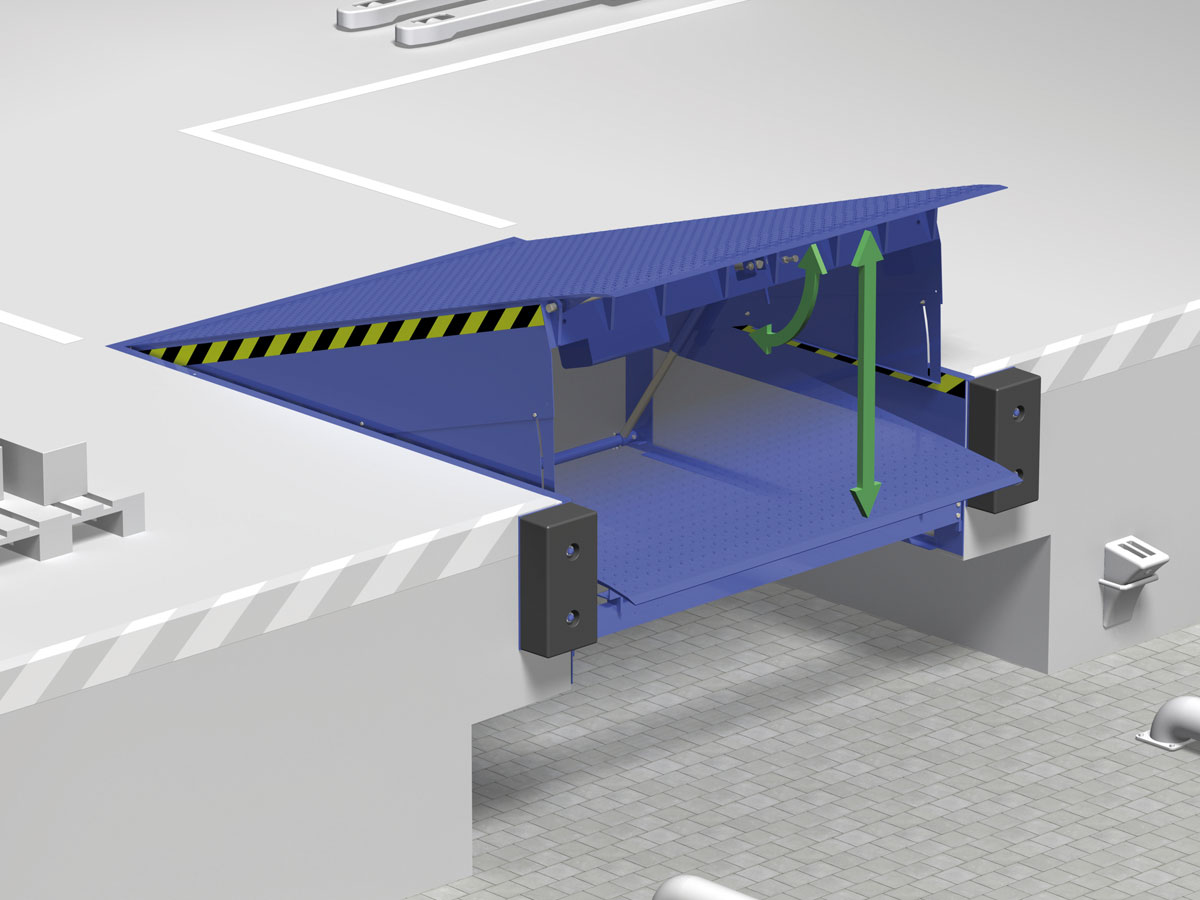

ArrowDock Levellers act as a bridge between the dock and the truck, allowing for smooth loading and unloading operations.

Choose from our swing lip dock levellers, telescopic lip or edge of dock models to suit your specific needs.

Hydraulic dock levellers with a swing lip are established as the basic version in the area of loading technology.

This option is suitable when the height difference between the dock and the truck bed is relatively small and consistent. It works well in scenarios where the majority of vehicles have similar heights and truck bed lengths.

They are easy to use; simply raise the bed with a push of a button, let the lip unfold at the highest point, then lower it to the back of the vehicle.

Our electro-hydraulic swing lip dock levellers are designed strictly in accordance with BS EN 1398 and manufactured to the highest possible quality using an automated production facility complete with robotised technology.

If your loading bay encounters varying truck bed heights and lengths, a telescopic lip dock leveller would be the more appropriate solution.

The extendable lip allows for greater adaptability, enabling seamless bridging of larger gaps and accommodating trucks with different bed lengths and heights.

Telescopic levellers are the most adaptable dock leveller solution as they feature a fully adjustable and controllable lip, allowing for a greater operating range and improved access to the back of the trailer. The precise movement of the bed of the platform and the lip ensures the perfect bridge is created from the vehicle to the dock.

Our electro-hydraulic telescopic lip dock levellers are designed to meet BS EN 1398 and manufactured to the highest possible quality using an automated production facility complete with robotised technology.

Since there's no need for costly modifications or pit construction, edge of dock levellers tend to be more affordable and offer a quick return on investment. They're also less maintenance-intensive compared to larger, more complex systems. Edge of dock levellers don't require any power to be opearted, they use a simple pole to raise or lower the ramp.